BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

URL: http://ijmse.iust.ac.ir/article-1-923-en.html

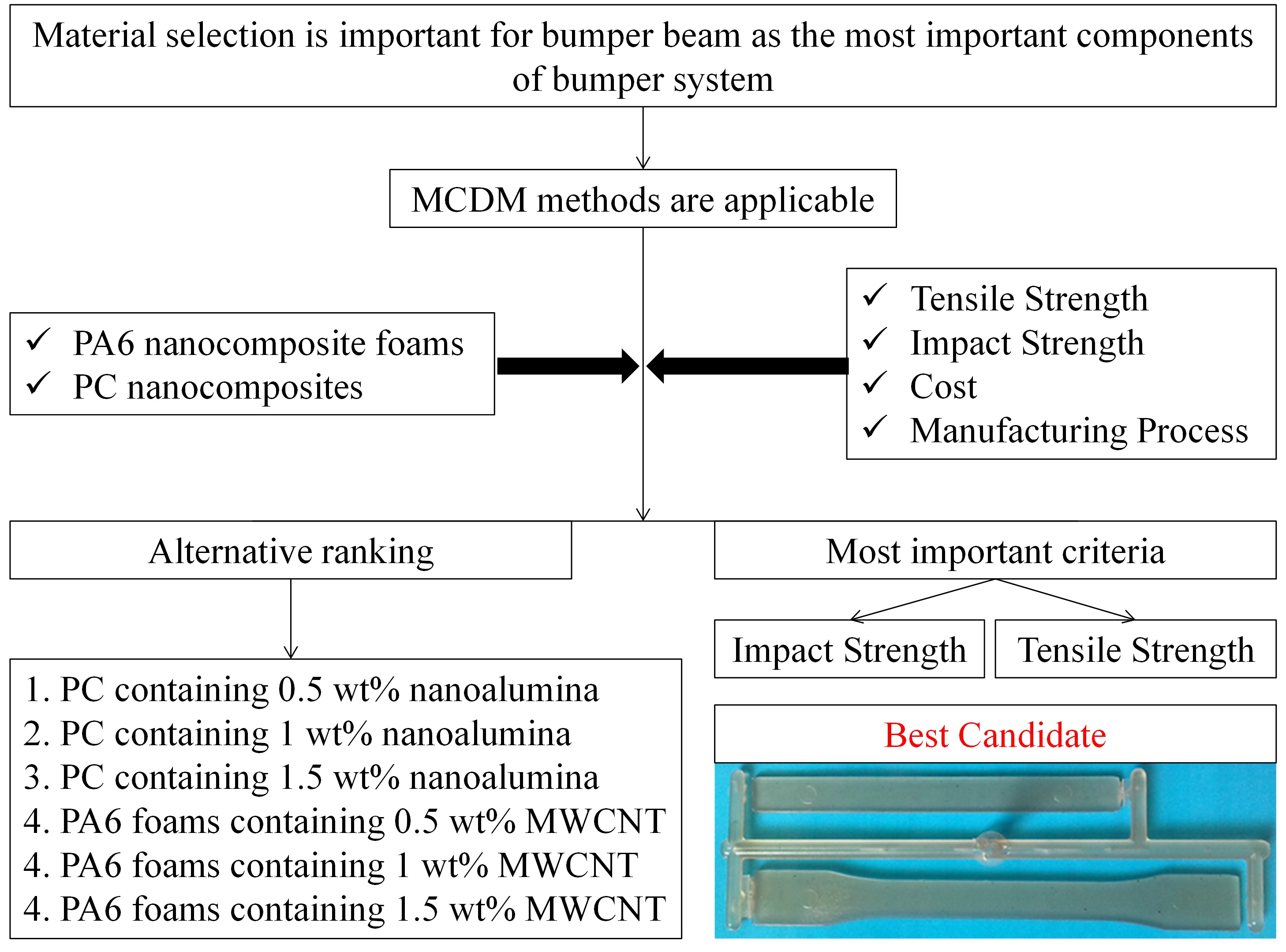

Material selection is a main purpose in design process and plays an important role in desired performance of the products for diverse engineering applications. In order to solve material selection problem, multi criteria decision making (MCDM) methods can be used as an applicable tool. Bumper beam is one of the most important components of bumper system in absorbing energy. Therefore, selecting the best material that has the highest degree of satisfaction is necessary. In the present study, six polymeric nanocomposite materials were injection molded and considered as material alternatives. Criteria weighting was carried out through analytical hierarchy process (AHP) and Entropy methods. Selecting the most appropriate material was applied using technique for order preference by similarity to ideal solution (TOPSIS) and the multi-objective optimization on the basis of ratio analysis (MOORA) methods respect to the considered criteria. Criteria weighting results illustrated that impact and tensile strengths are the most important criteria using AHP and Entropy methods, respectively. Results of ranking alternatives indicated that polycarbonate containing 0.5 wt% nano Al2O3 is the most appropriate material for automotive bumper beam due to its high impact and tensile strengths in addition to its low cost of raw material. Also, the sensitivity analysis was performed to verify the selection criteria and the results as well.

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |