Mon, Feb 9, 2026

[Archive]

Volume 20, Issue 1 (March 2023)

IJMSE 2023, 20(1): 1-11 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Rahimzadeh B, Jalaly M, Roshan M. An Investigation into Mechanical Properties of Aluminum Matrix Nanocomposite Reinforced by Graphene–Boron Nitride Hybrid. IJMSE 2023; 20 (1) :1-11

URL: http://ijmse.iust.ac.ir/article-1-2982-en.html

URL: http://ijmse.iust.ac.ir/article-1-2982-en.html

Abstract: (17726 Views)

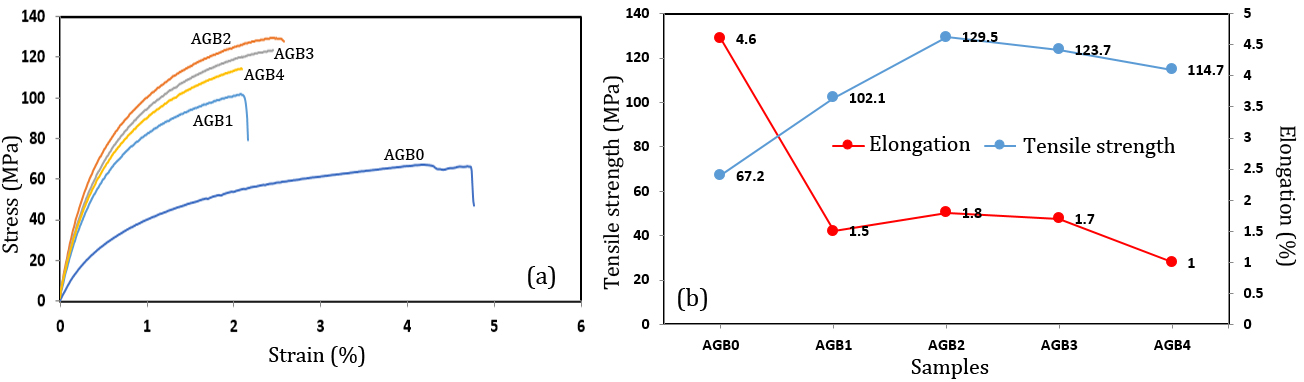

Considering the widespread use of aluminum composites in various industries and the emergence of nanomaterials such as graphene and boron nitrite (BN) with their unique properties, aluminum-based nanocomposite reinforced by the graphene-BN hybrid was fabricated at different percentages. For this purpose, the graphene-BN hybrid was prepared and subjected to wet milling along with the aluminum powder. The mechanical properties of the final nanocomposite which was consolidated using the spark plasma sintering (SPS) method were examined. Aluminum-based composite specimens containing 1 wt.% graphene–0 wt.% BN (AGB1), 0.95 wt.% graphene–0.05 wt.% BN (AGB2), 0.90 wt.% graphene–0.1 wt.% BN (AGB3), and 0.85 wt.% graphene–0.15 wt.% BN (AGB4) were fabricated and compared with non-reinforced aluminum (AGB0). The hardness values of 48.1, 51.1, 56.2, 54.1, and 43.6 Hv were obtained for AGB0, AGB1, AGB2, AGB3, and AGB4, respectively. Additionally, tensile strengths of these specimens were 67.2, 102.1, 129.5, 123.7, and 114.7 MPa, respectively. According to the results of the hardness and tensile tests, it was revealed that the AGB2 specimen had the highest tensile strength (93% higher than AGB0 and 27% higher than AGB1) and hardness (17% higher than AGB0 and 10% higher than AGB1).

Type of Study: Research Paper |

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |