Volume 14, Issue 4 (December 2017)

IJMSE 2017, 14(4): 81-99 |

Back to browse issues page

Abstract: (21653 Views)

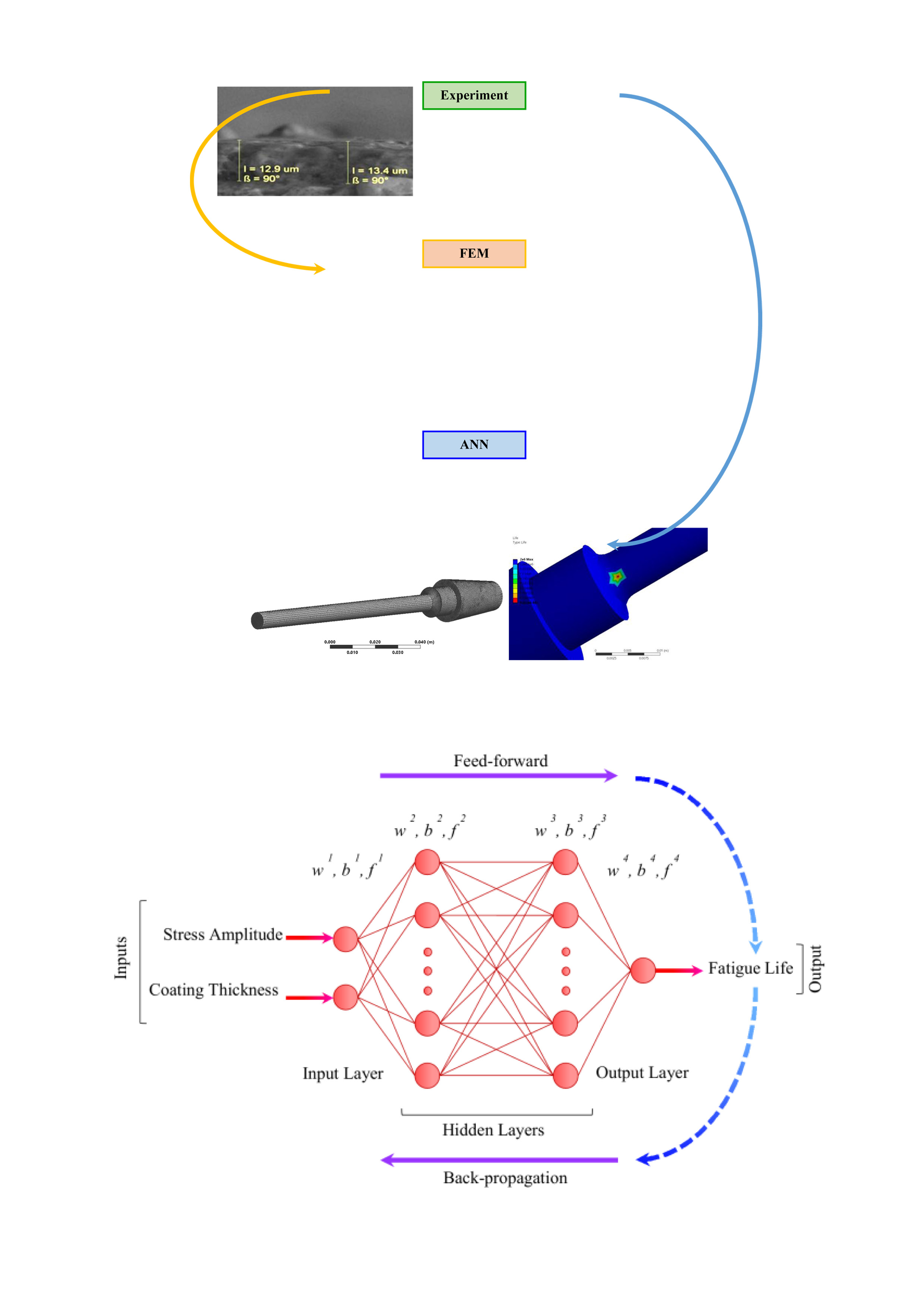

Hardened nickel coating is widely used in many industrial applications and manufacturing processes because of its benefits in improving the corrosion fatigue life. It is clear that increasing the coating thickness provides good protection against corrosion. However, it reduces the fatigue life. Thus, applying a thin layer of coated nickel might give an acceptable corrosion protection with minimum loss of the fatigue life. In the present study, the effects of hardened nickel coating with different thicknesses on the fatigue behavior of CK45 mild steel were experimentally investigated. After conducting the experimental tests, we carried out two different modeling approaches of finite element method (FEM) and artificial neural network (ANN). In the FEM modeling, an attempt was made to analyze the fatigue of the components by modeling the interface phase between the base metal and coating more accurately and using the spring elements; ANNs were developed based on the back propagation (BP) error algorithm. The comparison of the obtained results from FEM and ANN modeling with the experimental values indicates that both of the modeling approaches were tuned finely.

Keywords: Fatigue test, Nickel coating, Interface phase, Finite element method, Artificial neural network.

Type of Study: Research Paper |

Subject:

materials engineeing and special subjects

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |